wood

The term MDF stands for Medium Density Fiberboard and as its name suggests is a processed board made of sawdust that is the main byproduct of the wood industry with added resin that binds the chips under pressure to an artificial board. The material is homogeneous and has a smooth surface and a relatively precise thickness. Unlike solid wood, the MDF is more stable in terms of flatness and is less likely to change its length over time. MDF can be coated in few methods, such as: laminates, Formica and melamine as well as different kinds of paint. The MDF is common in the furniture industry for cupboards and closet doors, as well as many other uses. The material is relatively inexpensive and therefore attractive.

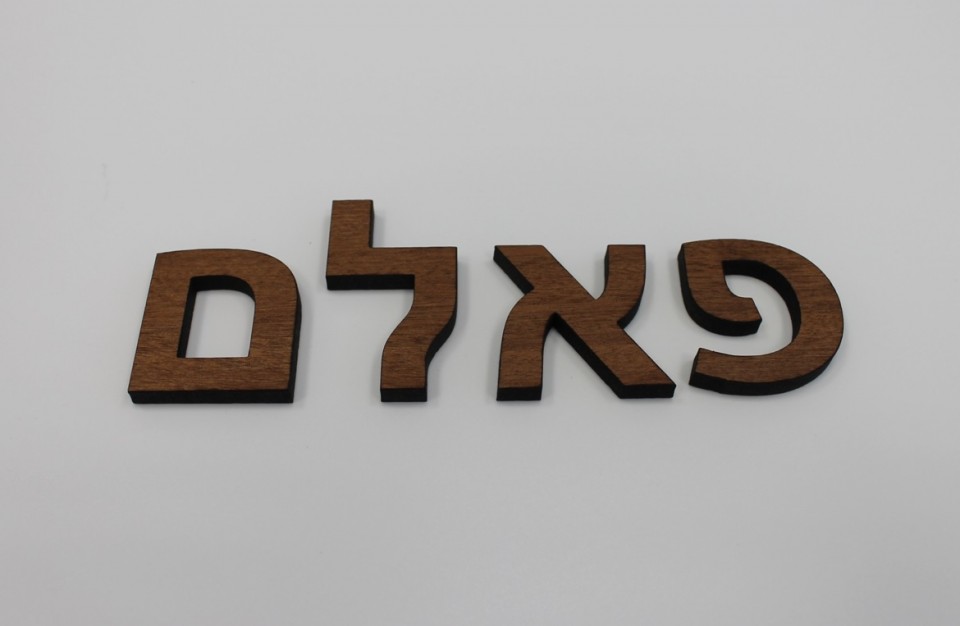

Laser Cutting of MDF

MDF laser cutting can yield very impressive products and add alot of value to this relatively inexpensive material. We can cut full boards of MDF (244X122 cm) up to a thickness of 17 mm.

Uses - stencils and jigs for cutting and assembly, molds for UV printing, storage and display boxes, toys and games, lettering for painting, display installations and more.

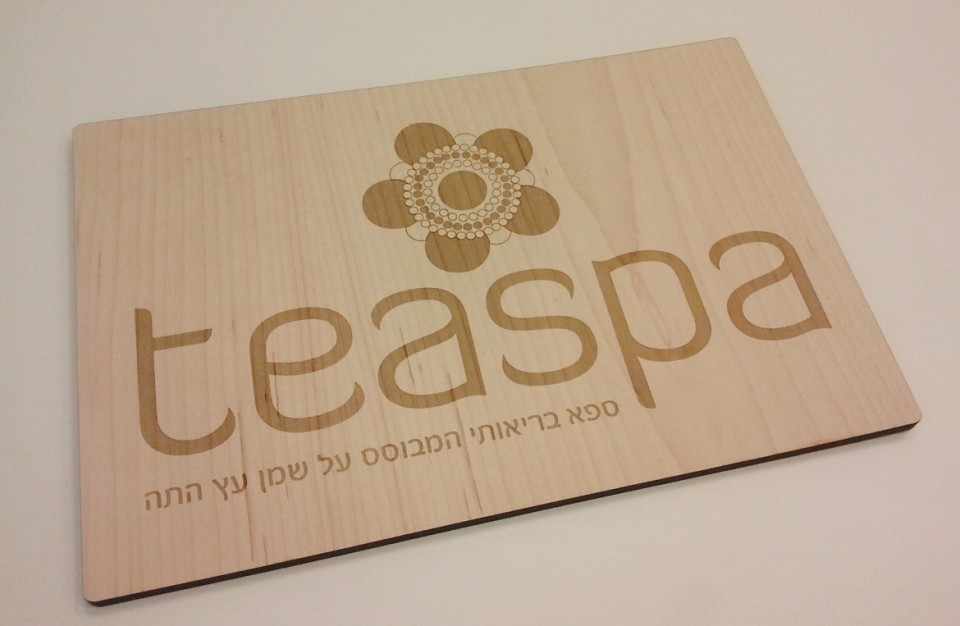

Laser Engraving on MDF

As a dense and uniform material, MDF is ideal for laser engraving yielding very uniform and fine results. It is possible to engrave thin lines or complicated areas as designed and saved in the graphic file. The engraved graphic can be delicate and shallow or strong and deep to create more dramatic effect.

Uses - engraving signs, engraving textures for walls, stencils, furniture parts, and more.

For a quote - Press Here!