Polymers

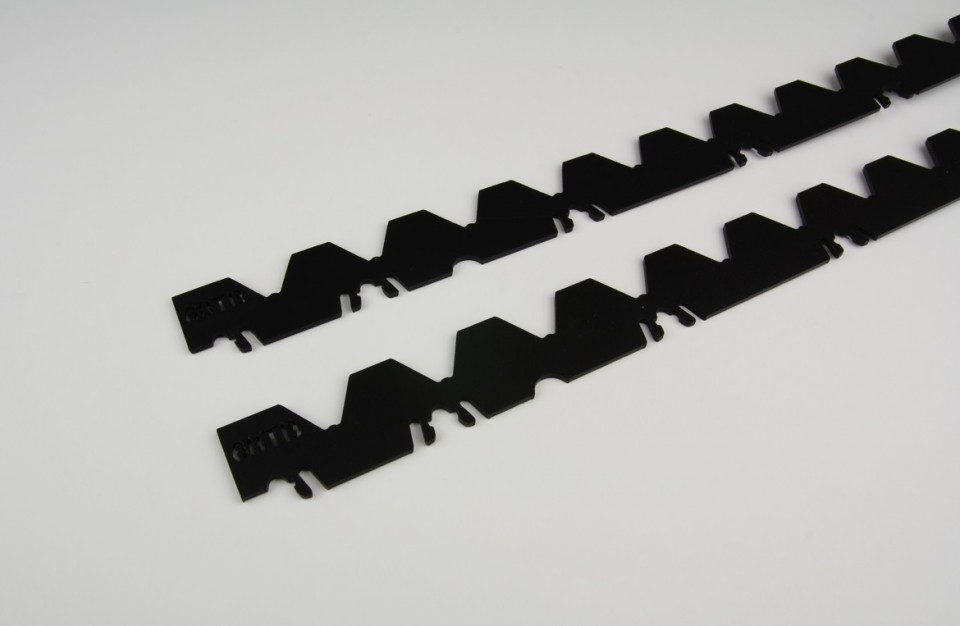

astic polymer produced in a process called polymerization. It is characterized by good mechanical properties, excellent thermal resistance, moisture resistance and chemical resistance. It also excels in flexibility and in low friction coefficient.

Laser cutting of polypropylene

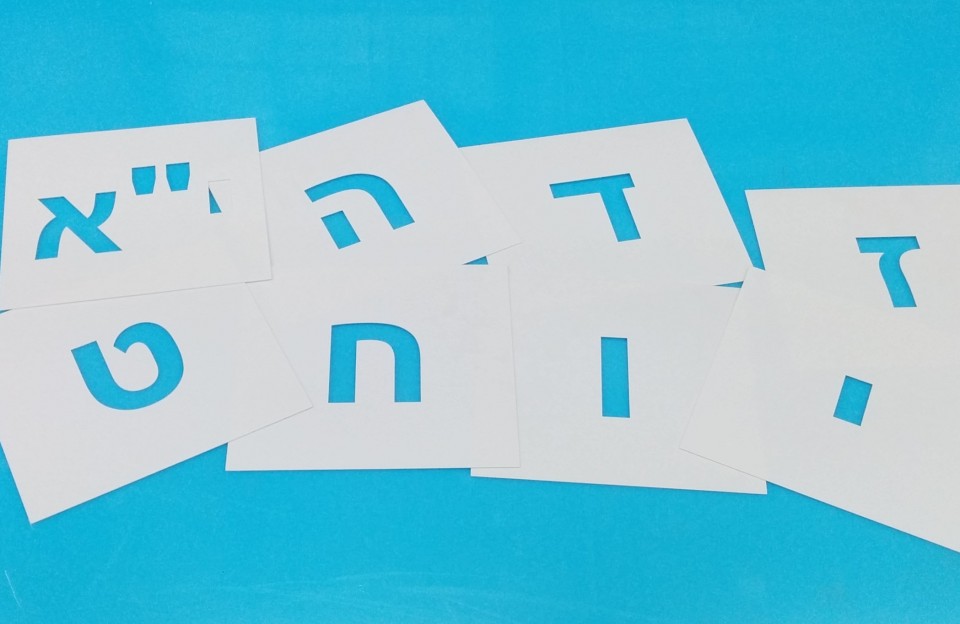

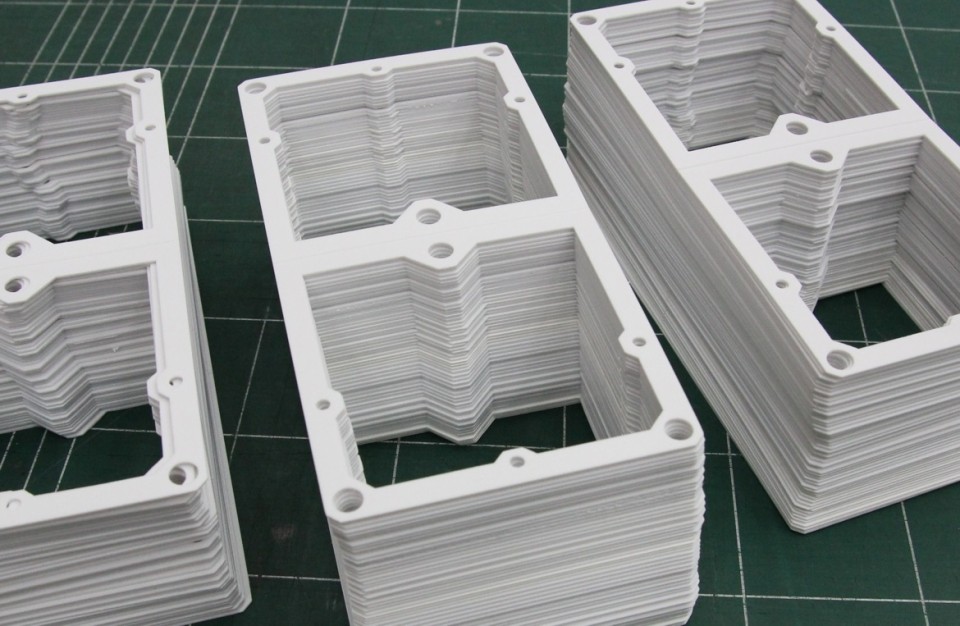

Polypropylene comes in a variety of colors of 0.3-0.4 mm thickness and in less colors in higher thicknesses (up to 1.6 mm). It can be laser cut and laser engraved relatively quickly and the cut line is not sharp and even shrinks and retracts slightly, so that the cutting line (KERF) is wide relative to other polymers such as acrylic.

Laser engraving of polypropylene

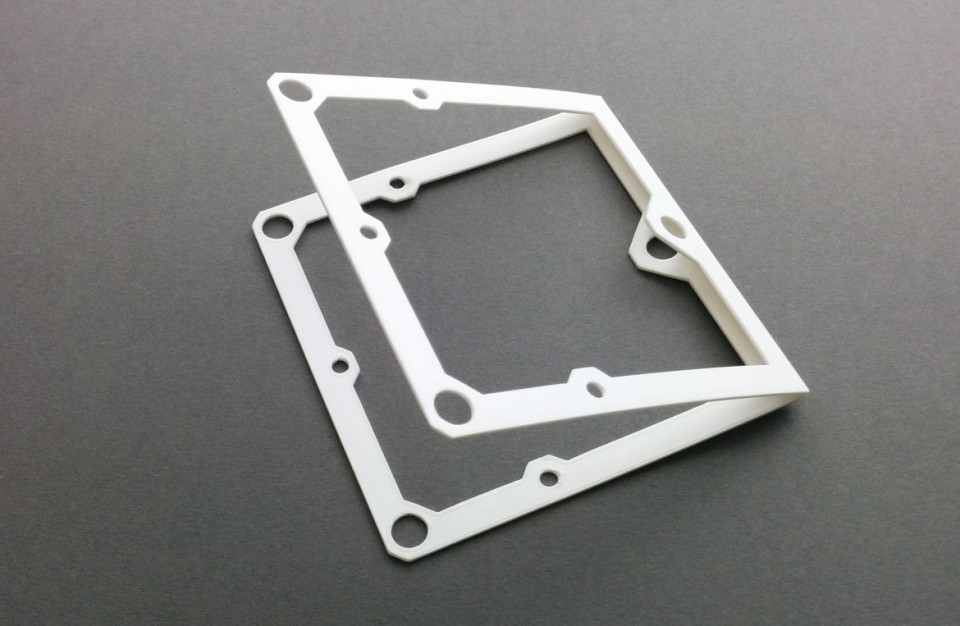

Due to its durability and flexibility, it is highly suitable for folding. The laser engraving enables the production of precise folding lines and thus enables the creation of smart layouts that can be folded and flattened many times without fear of the material being torn. It is also possible to burn areas and incorporate a logo engraving onto the material. Burning does not change the color and only slightly detracts from the material.

Applications - Stencils for roads marking, stencils for painting parking areas, wall stencils, stands, connectors, plastic strips, base tags for stickers and electronics, electrical appliances, folding cases, lampshades and much more.

For a quote - Press Here!