Metals

Stainless steel an alloy containing over 10.5% chromium and less than 1.2% of carbon. Its resistance to rust and corrosion distinguishes it from ordinary steels that are alloys of iron and carbon. Its long durability, low price and unique brilliance have increased the demand for stainless steel that nowdays can be found in a wide range of uses: kitchen tools, work tools, industrial piping, industrial kitchen surfaces, medical equipment and more.

There are many types (over 150) of stainless steel, the main ones are:

301/302 - for the manufacture of springs and knives.

303 - for machining.

304 - for general use.

310 - for high heat resistance.

316 - For wear and corrosion resistance, especially suitable for the food industry.

321 - Contains titanium and is suitable for parts of the aviation industry.

430 - Usually comes with a mirror finish and therefore is suitable for reflectors.

18/10 - Cutlery and pots containing 18% chromium and 10% nickel.

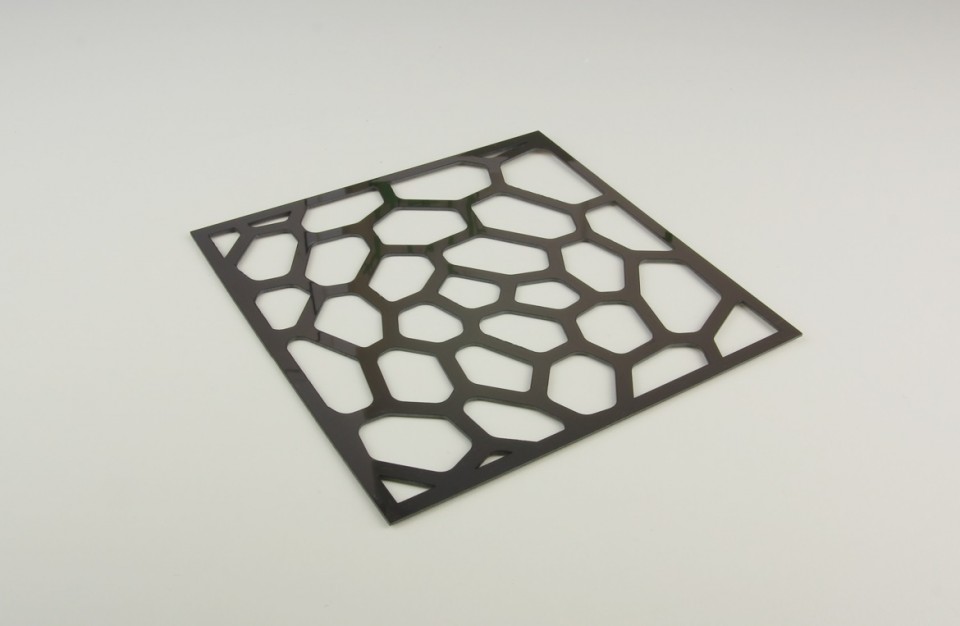

Laser cutting of stainless steel

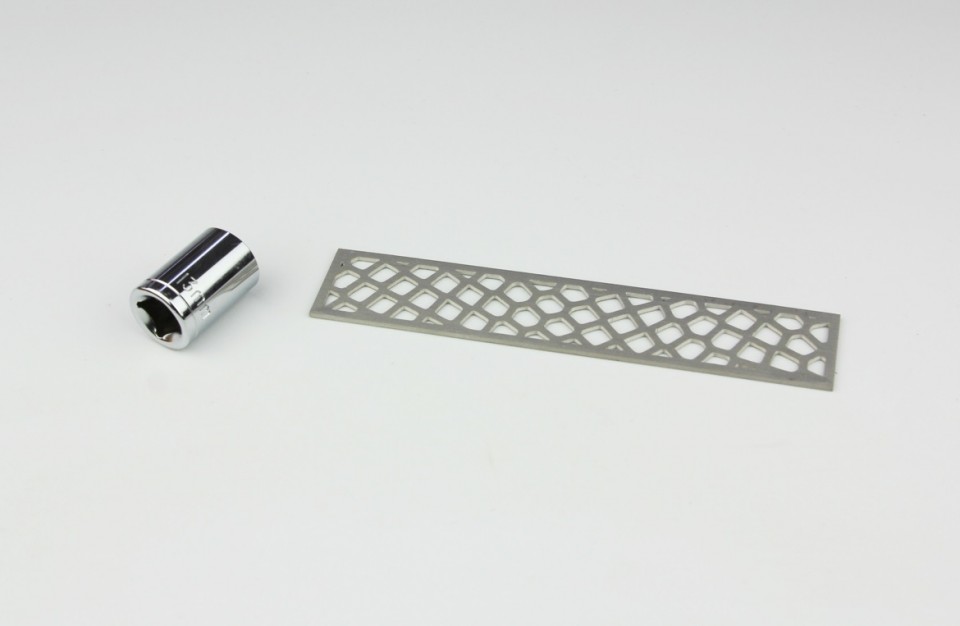

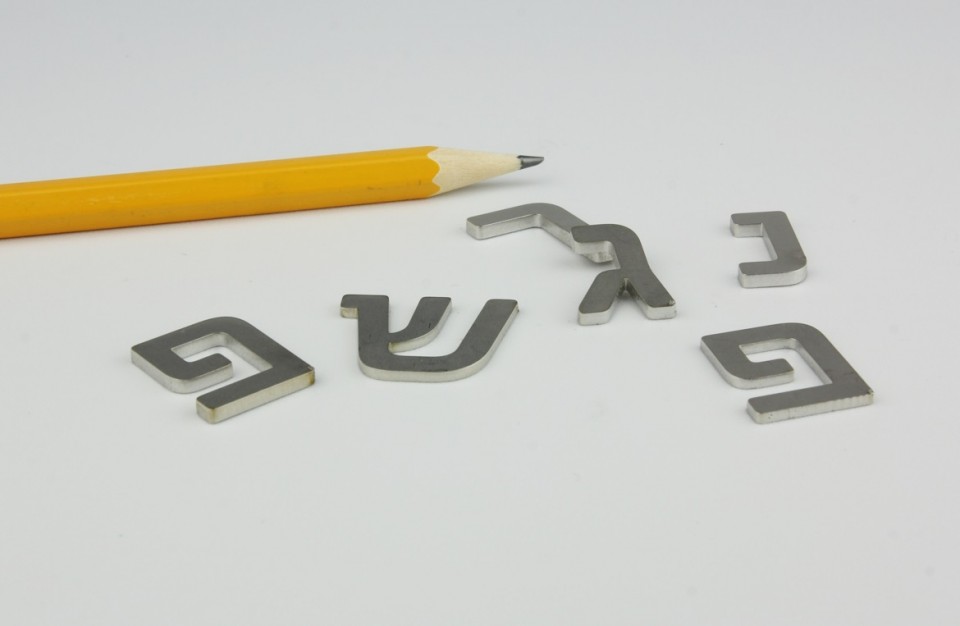

In Lasercut4 we cut stainless steel up to a thickness of 3 mm and hold a variety of thicknesses in stock.

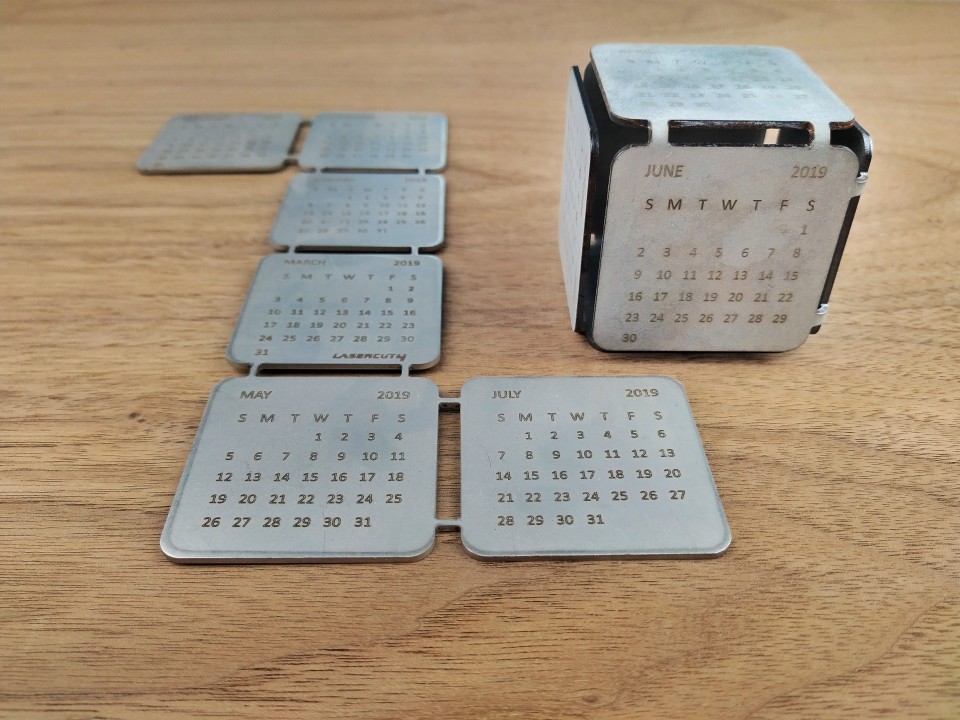

The advantages of cutting stainless steel with laser are many: high speed, accuracy, relatively clean finish, minimal loss of material and more. Proper design allows you to use the plastic properties of the metal in order to create 3D parts. Laser cutting of stainless steel is common in medical development, clean-room products, machine parts, laboratories, and products for moist and wet environments.

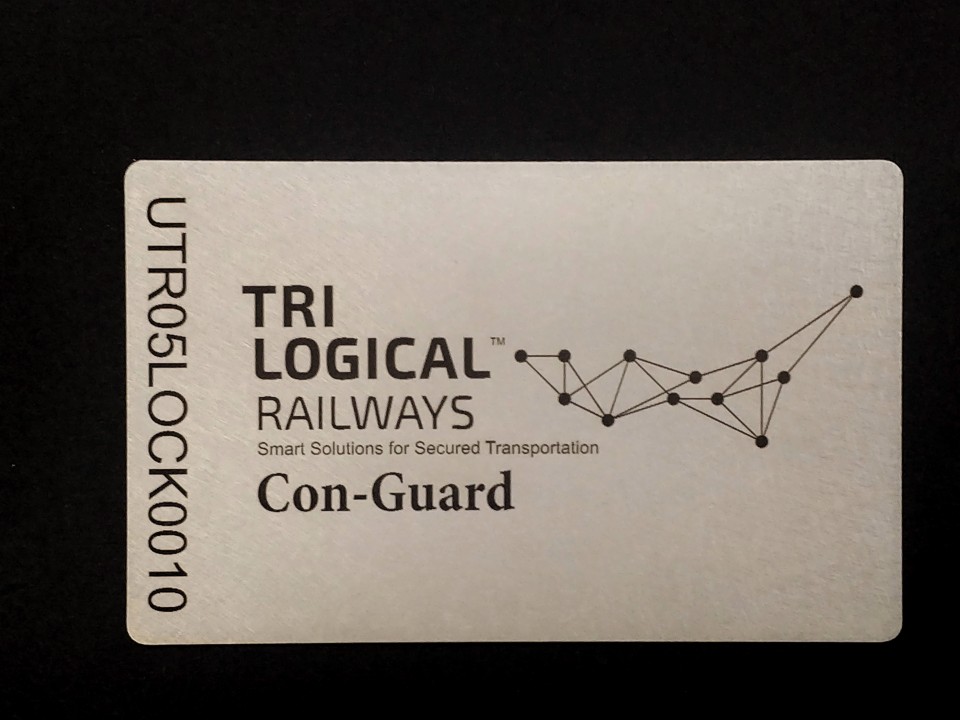

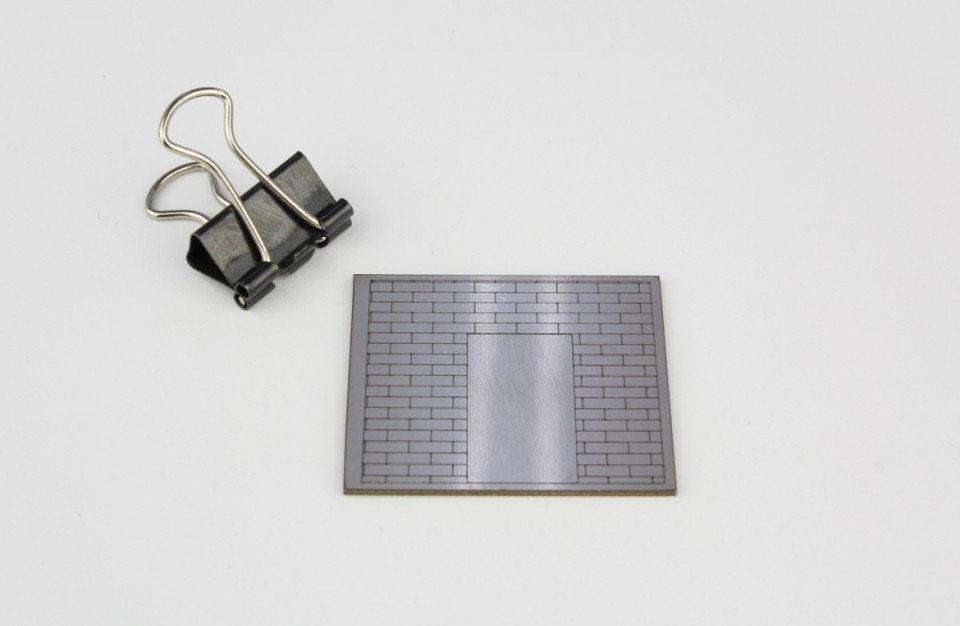

Laser marking on stainless steel

Laser marking on stainless steel is possible at flat areas on the surface of the product. Marking on the surface of the steel is permanent and non-erasable. Variable information, pictures, logo or barcode can be marked resulting in blackened graphics on top of the silver surface.

For a quote - Press Here!