Metals

Aluminum is the most common metal. Its unique low weight - 2.7 kg per liter, about one third of iron, makes it very suitable for many products and is used in many industries: windows and doors frames,automobile, bicycles, aviation, etc. Under moist air conditions, a thin layer of aluminum oxide - alumina - is developed over the surface of the metal and it actually produces a layer that protects the aluminum from corrosion, which in fact produces the dull gloss characteristic of the material.

One of the common finishes for aluminum is anodized coating - an electrical process which while occurring the aluminum part is used as an anode in a sulfuric acid solution. This process actually thickens the alumina layer and allows for a colorful finish by adding the desired pigment.

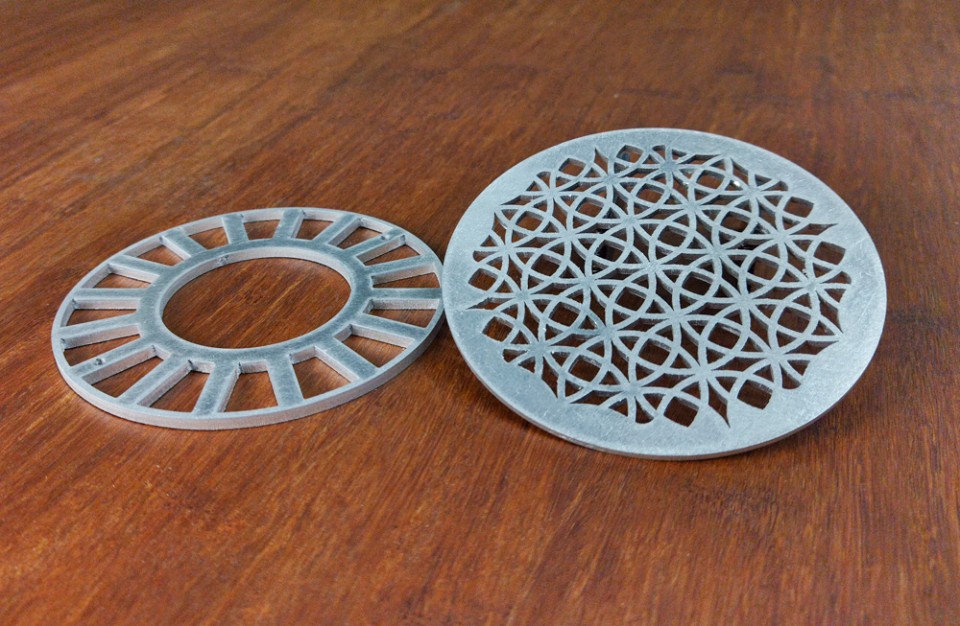

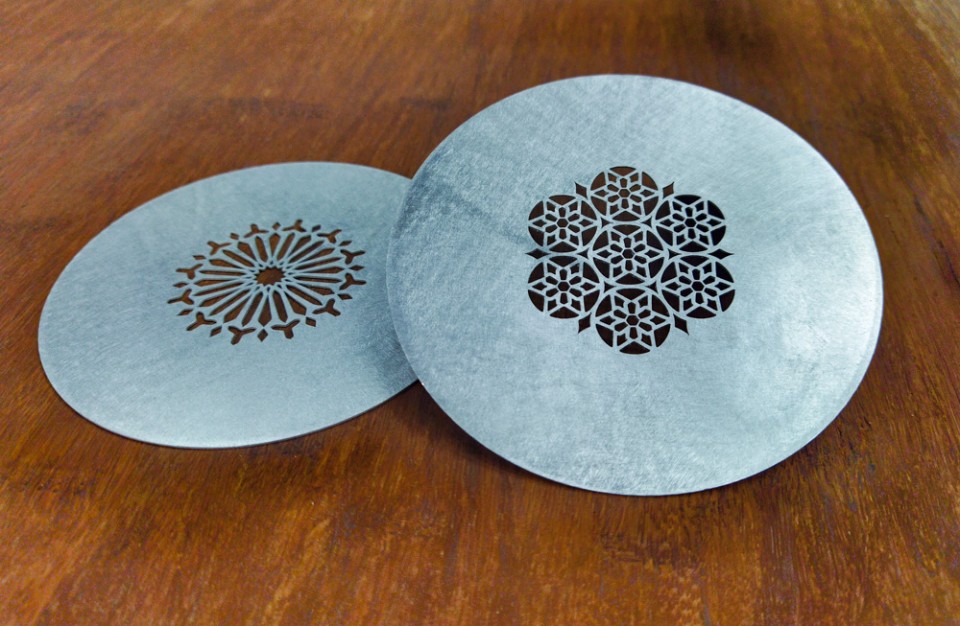

Laser cutting of Aluminum

In Lasercut4 we cut aluminum up to a thickness of 3 mm and hold a variety of thicknesses in stock.

Cutting Aluminum with laser works well and results with a fine finish. It is possible to cut a variety of thicknesses, as well as anodized aluminum. Laser cutting allows for high accuracy, the ability to produce complex and detailed graphics (for example, thin grid or lace cutting) and high repetition to produce a homogenic serial. The uses are diverse, ranging from mechanical parts for the industrial markets, through designed elements for interior and exterior uses for private needs at the level of the home user such as stencils, ornaments, etc.

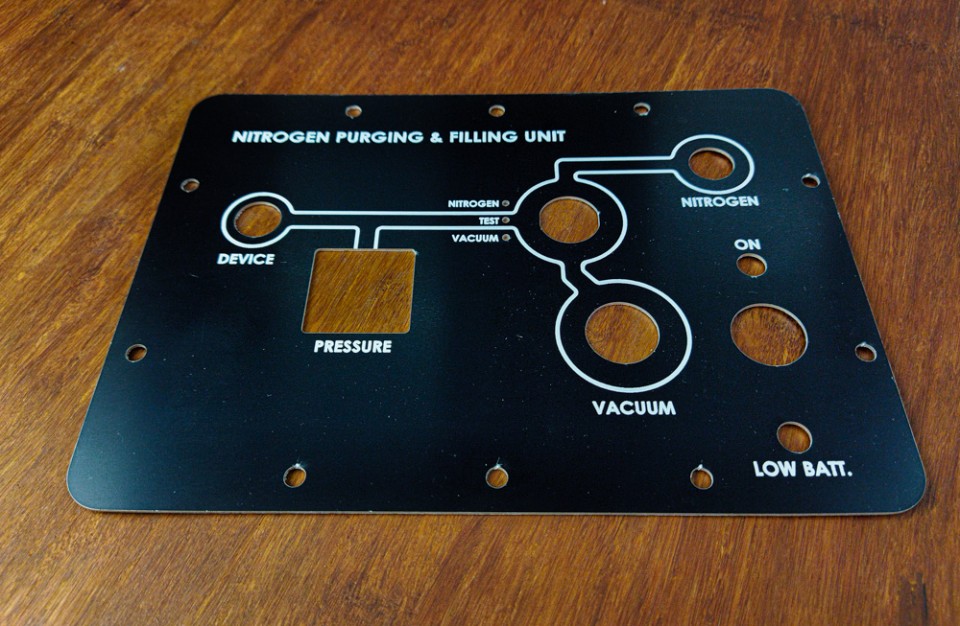

Laser engraving of aluminum

In Lasercut4 we cut and mark aluminum using both CO2 and FIBER laser technology, we have extensive experience in engraving on aluminum anodized plates. The engraving is being done on the coating/paint layer and actually exposes the aluminum underneath. This way you can mark text, linear graphics, barcodes or rasterized areas. The durability of the mark is very high and its advantage over print/color is that it does not fold or fade over the years.

For a quote - Press Here!