Metals

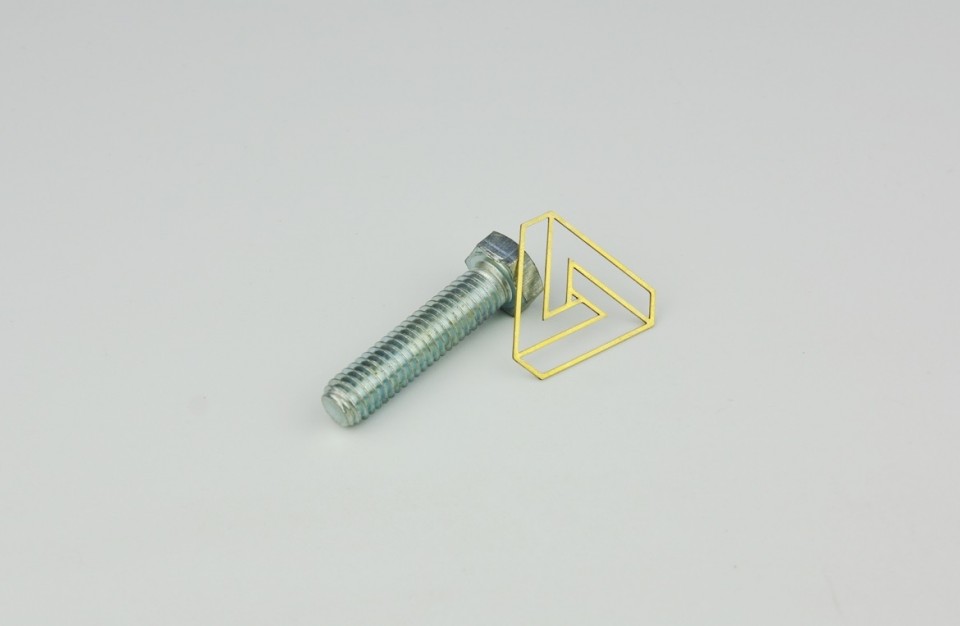

Brass is an alloy consisting of two metals: copper and zinc - which has a golden color that changes according to the proportion of the zinc and the copper in the alloy. The composition of the elements also defines the mechanical properties of the brass (hardness, strength, etc.) and changes in them or the addition of other elements, to the alloy, will change the metal properties to suit mechanical processing such as laser cutting.

Brass is known for thousands of years, and tends to be confused with bronze, which contains copper and tin. Its gold-like color and it's relatively cheap price make it very useful for jewelry making and decoration design. It has a relatively low melting point (about 900°C and above according to its component ratio) and is easy to cast. In addition, the metal can be recycled. The metal is harder and stronger than copper, with lower electrical conductivity than copper. Used for cold processing such as rolling, stamping, pressing and pulling. Easy to weld, relatively resistant to corrosion, turns green in humid atmosphere. Can be coated in metals such as tin, gold, silver, nickel and more. Brass is Used in parts such as locks, faucets, gears, handles, tools and accessories that prevent spark when struck (used near flammable materials) etc.

Brass is also found in many products in the domestic and industrial environment: connectors in electrical components, electrical outlets and switches, shimmers, sliding bearings, designer products, musical instruments, knobs and zippers in the fashion industry.

Laser cutting of brass

At Lasercut4, we cut brass up to a thickness of 3 mm and we hold a variety of thicknesses in stock.

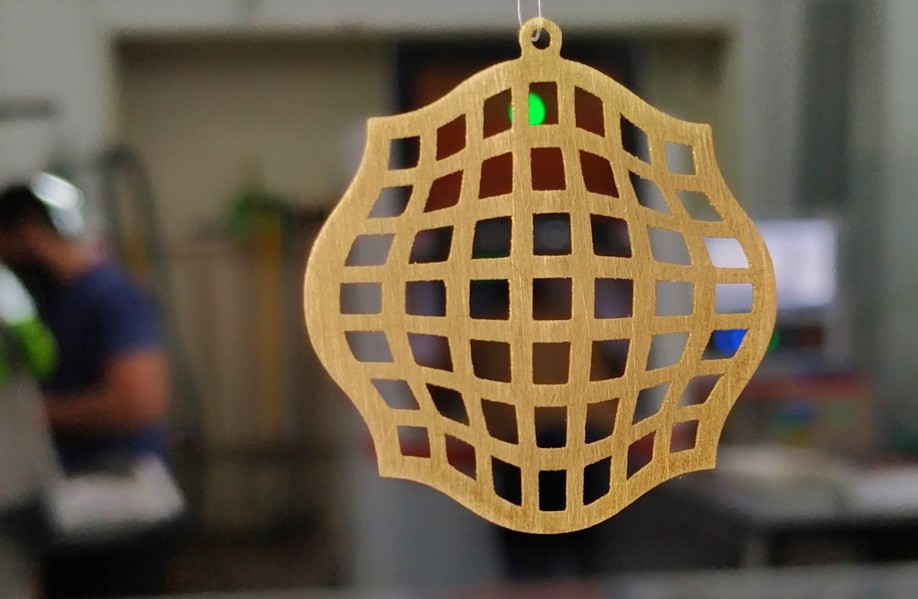

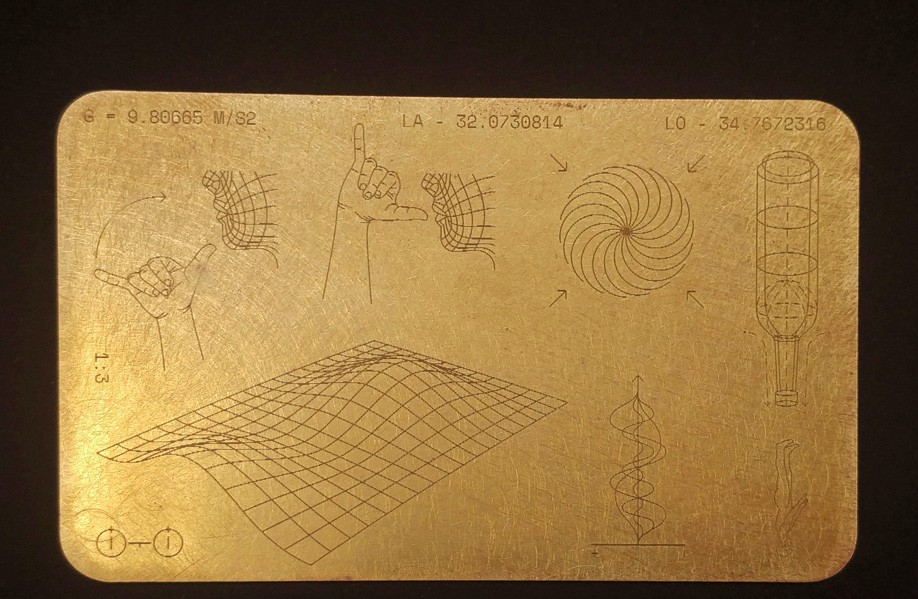

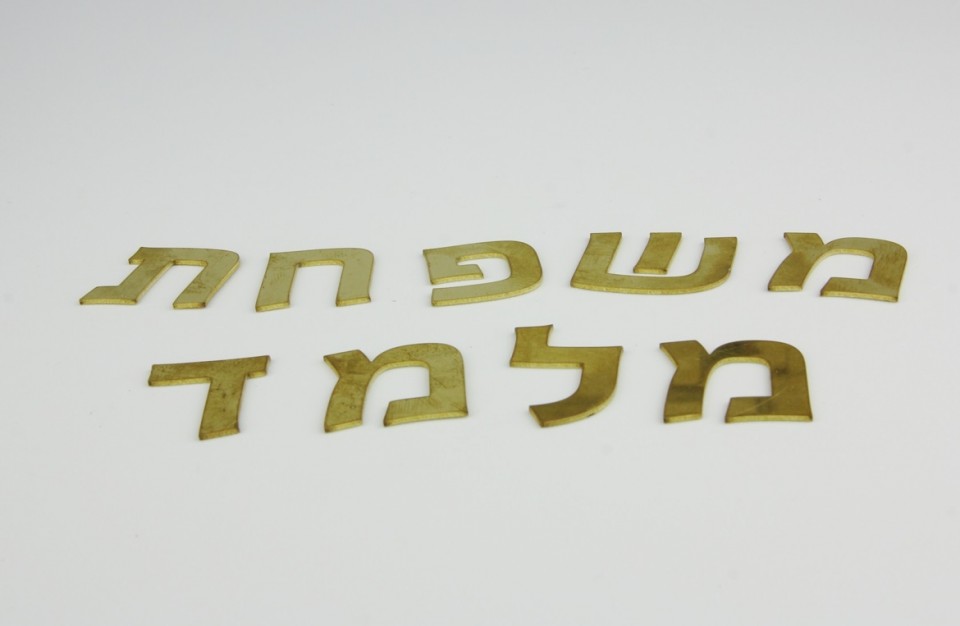

We can cut complex lace patterns, and decorative elements for indoor and outdoor use. It is especially useful for laser cutting of a variety of thicknesses - even in thin sheets that are less than 1 mm in thickness.

Laser engraving of brass

Brass is a reflective metal which makes it a bit more difficult to cut, similar to other reflective metals such as gold, copper, bronze and aluminum. For this purpose we use Fiber laser machine which is the most suitable technology for cutting such metals. Laser cutting process allows single production as well as serial production according to a drawing/graphic file that makes the production process relatively fast and cheap. Jewelry industry is a direct beneficiary of the technology since it is possible to produce very detailed and delicate cuts in brass.

The advantages of using laser technology when cutting brass (as well as many other metals) are:

- Quick execution of the work - sending a drawing file by Email and quick production.

- Cost savings versus other metal processing (water cutting, milling).

- Good cutting speed.

- The quality of the cutting egde is good and smooth - minimum scabs.

- Reduced energy consumption (economically friendly and environmentally friendly).

For a quote - Press Here!

More relevant information:

Article about materials and laser technology