Materials

On this page you can find information regarding composite materials that we can process with our laser machines.

Composite Materials

Composite material is a material used in the engineering field as a raw material made up of a number of different materials combined together into a single material with new properties. Each of the components used in the composite material gives it unique properties that together define its final quality. The bond between the elements in the material is made by adhesives (also have unique properties) that maintain each of the components in its complete structure. Usually the composite material will be a product of fibrous materials or flakes that are grounded in another material that fixates them to the new desired structure, such as concrete.

Among the new features obtained in the composite material are high toughness in relation to low weight, good temperature resistance and other durability properties. These enhanced properties designate the material for use in areas such as aeronautics, transportation, design and aerospace. The materials are considered expensive and are constructed using hand made techniques resulting in longer times and higher costs of production.

Sheets can be lasercut from a composite material of various types and thicknesses.

Since each material has different properties, a cutting test must be carried out in the designated material in order to obtain optimal settings.

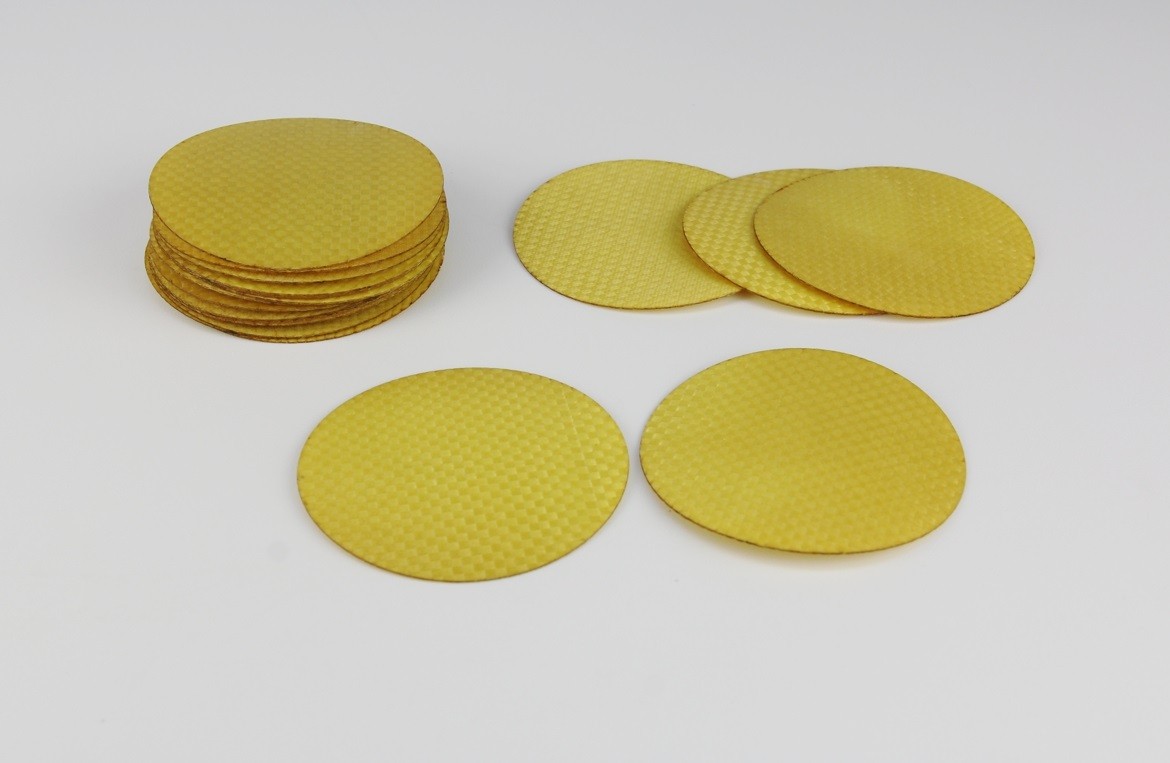

Laser cutting of Kevlar parts - 1 mm thick composite sheet

Laser cutting of Kevlar parts - 1 mm thick composite sheet

Laser cutting of Kevlar parts

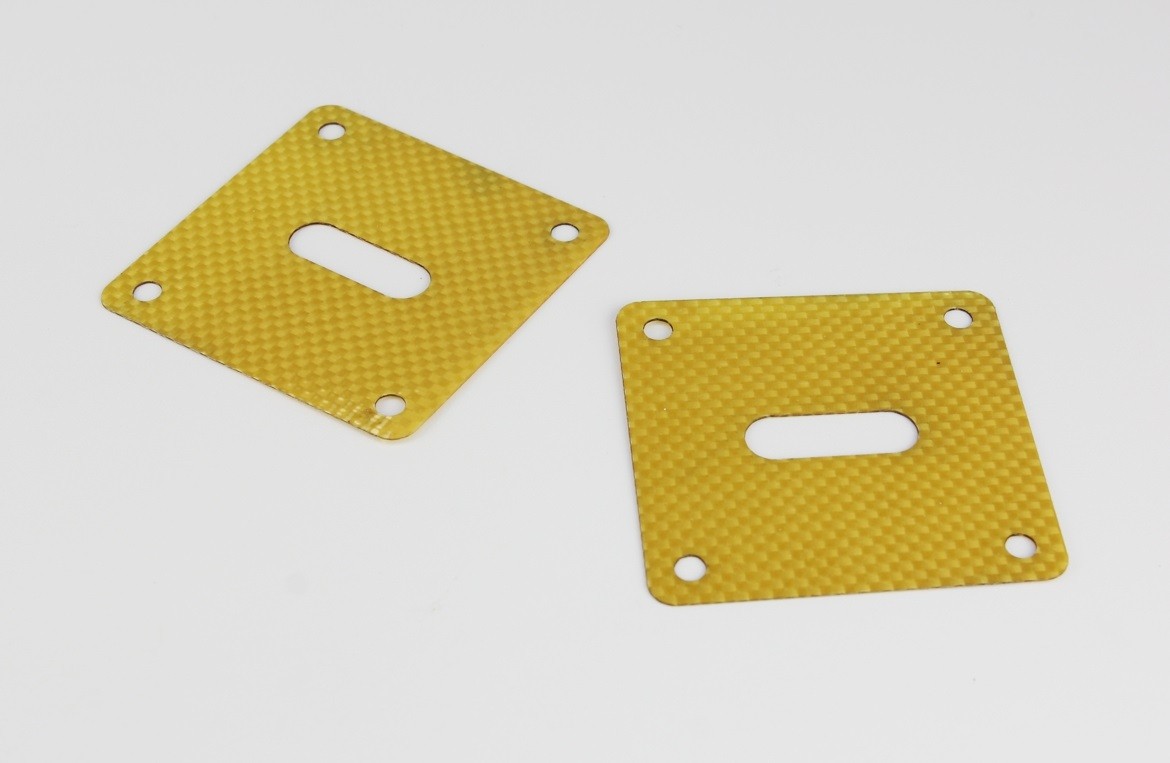

Laser cutting of Kevlar parts according to technical drawing

Laser cutting of Kevlar parts according to technical drawing

HPL

HPL stands for High Pressure Laminate and is a thin, rigid panel made of high temperature and high pressure molding. The sheet is made by pressing layers of different papers, with adhesives resulting in a uniform material. The material obtained is relatively resistant to scratches, bumps and damage, strong, does not absorb moisture and can be easily cleaned. There is a very large selection of HPL panels in different colors, with a glossy or matte finish or with an embossed finish that creates texture that is felt by hand.

Laser cutting of HPL can give good results when using relatively thin sheet of material (less than 1 mm). Due to the high density of the HPL, very detailed results can be achieved when it is laser engraved. Please consult with us whenever you wish to cut or engrave HPL.

Usable for - various carpentry work, furniture, special signage, surface cladding, jewelry design and more.

For a quote - Press Here!

More relevant information:

Article about materials and laser technology