Laser Engraving on wood

Artistic engraving on wood

Artistic wood engraving is a field of art that uses an handicraft technique and an hot burning tool to preform artistic drawing on the wood (also called pyrography - from Greek, fire writing). The process includes drawing on various raw materials and different wood types, burn them in high heat using a manual tools which act like drawing tool. The burn drawing is done on flat panels made of polished wood and polished as well as on various leather sheets.

Some of the tools allow you to control heat intensities and have variable types of edges that allow for different effects such as creating a gradient effect, stripes or other shapes. Usually these tools are electric tools, and include metal parts (or hot wires) that transfer heat to the working area. Another way is to burn the material by using optical lenses that coordinate the sun's radiation to the wood surface.

The colors in the picture range from shades of gray and light brown to shades of dark brown and black. These brightness changes between the colors create a high contrast that allows the image to get the look according to the artist's decision. The work in this technique is intensive, manual and requires artist's touch and creative thought in order to convey the most detailed picture to the wooden board. In order to achieve impressive results in this work, the artist must have extensive experience in this art and be familiar with the effects of each tool he uses on each type of material he choose. It takes a lot of experience and artistic vision to produce special works that appeal to the eye.

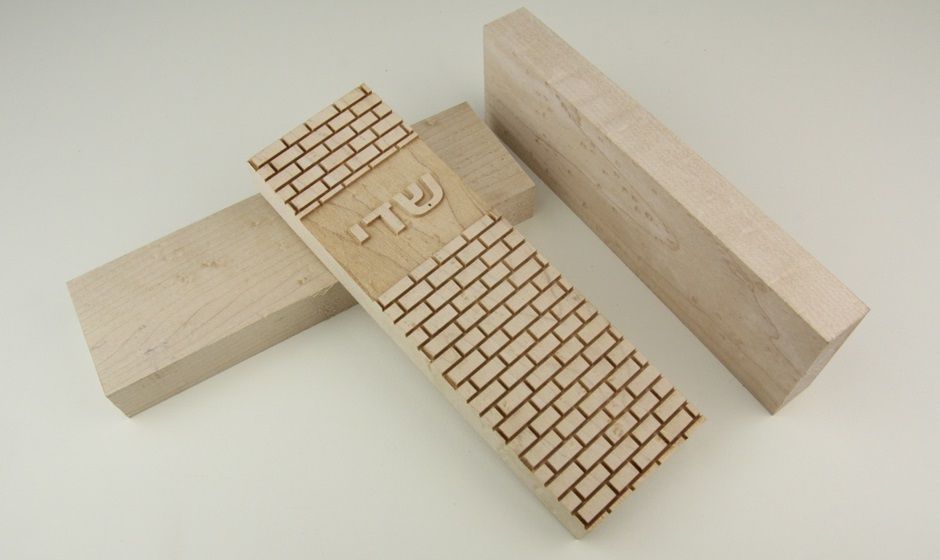

Laser engraving on a wood - sign at the entrance to the house

The finished products can be painted in acrilic paint, oil paint or, alternatively, preserved by applying oil coating to the entire work, giving it additional depth and making the appearance more attractive. Another option is a transparent varnish coating (glossy or matte finish) that protects the burning work and gives it a long life.

Laser Engraving on wood

Like the work tools that use the sun light and optical lenses to create the image, laser technology also serves as a tool for the art of pyrography. At the base of the technology, a very strong and focused light beam which slightly burns the surface of the raw material, similar to the manual tools. Because laser power can be controlled, it is possible to set the heat levels and actually affect the color tones. The process involves loading the graphics we want to engrave in to the computer and adjusting the appropriate laser power to perform the burning marks. From this stage, the machine operates independently and reproduces the laser engraving graphics on to the surface of the raw material.

In fact, when you laser engraving wood, it is possible to resemble a complex and rich detailed handwork, in a way that is almost unrecognizable by an unprofessional eye. The Laser engraving result on wood is influenced by a wide variety of factors such as wood type, the clarity, wood hardness, The amount of moisture in the wood and the amount of natural oil in the wood. usually, engraving is naturally darker and distinct in light trees, which are easily and faster than hardwood, but the amount of details can be reduced. The direction of the fibers within the wood plate affects the burning effect and depending on the intensity of the burn - sometimes the wood image is "seen" through the burn.

Laser engraving is a technology adapted to the technique of pyrography and enables the production of images in a fast, accurate and high repetition. The ability to obtain various finishes such as paint, lacquer or impregnation with special oils, evokes the natural appearance of the material.

Advantages of Laser engraving:

Speed - Because the movement of the laser on the surface of the material is fast and yet very precise movement, large areas of graphics can be quickly engraved. In addition, the ability to controle the Laser beam power quickly enables the application of several varying shades along one beam transition.

repetitiveness - Because the laser is computer driven, it knows how to repeat the same path at the same points, thus creating the same image by burning each time anew. It is clear that the response of the raw material still effect the outcome result, but in terms of laser operation it is the same operation that can be performed many times.

Variable information - Dependence on the computer with it's operation file which defines laser parameters, it allows you to change the engraved graphics from product to product at no additional cost. In fact you can engrave different information at any time and for each product and thus offer custom graphic design.

Price - Laser cutting can offer a product that is much cheaper in relation to the same product made by hand. engraving a large number of products makes the price even lower where technology has a greater impact on costs. Another aspect of price reduction is the option to laser engrae without the need of additional processing tools that may cost money too.

Laser engraving on a wooden case - floral graphic

The wide selection of woods offers many options of patterns, colors (gray, black, brown and earth) and other features that suit this working style and technique. The wood as solid and hard material is a great material to feel by hand and with nice appearance, has a prestigious reputation and is characterized by durability and a long life span. These qualities make it a prestigious raw material that has added value when the recording technique is applied to it accurately and correctly.

Other examples of Laser engraving on wood:

Laser engraving on eucalyptus tree - house entrance sign

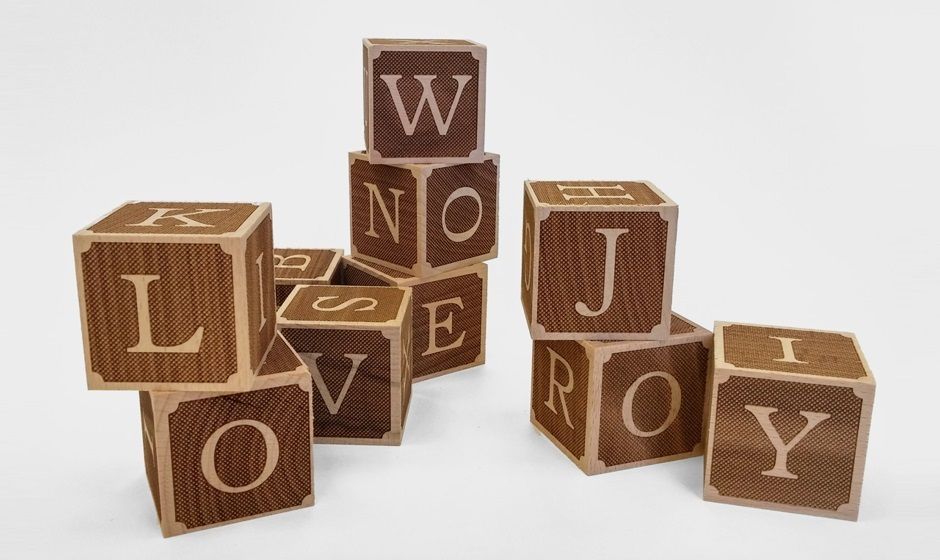

Laser engraving on maple wood

Laser cutting of Three-dimensional decorative element in maple wood

Laser engraving of text on pine wood

Laser engraving of letters on Beech wood

At Lasercut4, We offer laser cutting and laser engraving services on a wide variety of woods for a wide range of industries as well as the private sector. The equipment, facilities, and machines that we use enable many options for product development, branding and production.

We certified for ISO9001:2008 quality standard and are constantly improving in all aspects of our operations.

Related Articles:

Laser engraving and marking - A variety of materials suitable for laser marking and laser engraving with examples of applications.